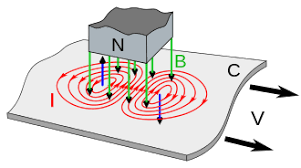

The inspiration for this project came from wanting to investigate the phenomena of “eddy currents.” Eddy currents are loops of electrical current that are produced when a conductive material passes through a magnetic field or vice versa. The faster the movement between these two interacting components, the greater the current grows. The special thing about eddy currents is that they create a magnetic field that opposes the changing magnetic field that the conductive material is surrounded by, which can be used to slow the motion of the conductor. In our project’s case, we wanted to evaluate the viability of using eddy-current-based braking compared to traditional automotive braking systems.

Photo: https://en.wikipedia.org/wiki/Eddy_current

In the case of our project, the conductor we are working with is an aluminum 6061-T6 rotor that spins upon a weighted axle. Our magnetic field is created through two industrial-sized electromagnets, mounted in-line with each other on each side of the rotor. Depending on how fast the rotor is spinning, the amount of eddy current formed within the rotor varies. We can also create more eddy current by increasing our magnetic field, which is done by sending more power to our electromagnets. Essentially, the more eddy current produced, the more braking power produced as well.

We decided the best implementation of eddy-current-based braking, or electromagnetic braking, on automobiles was to use it as an accessory braking system to standard friction brakes. While electromagnetic braking can be responsive at high speeds, it does not have the capabilities of working at slow speeds, because it relies on the changing magnetic field produced by the spinning of the rotor. And in the application of braking for automobiles, the brakes must be responsive at slow speeds and be able to fully halt the motion of the vehicle. Because of this, we have also incorporated a hydraulic braking assembly to our project that can sustain a holding force.

As a result, the intended purpose of having a secondary electromagnetic braking system is to extend the life of friction brakes by utilizing electromagnetic braking at high speeds, ideally on highways and freeways.